About Us

Get to Know Us

About MS Design Innovations

We have over 30 years experience and considerable hands-on knowledge in the design and development of process equipment.

Our mission statement is simple, to make the design and the services we offer an asset for your company, to provide engineering solution which is innovative, cost effective and in a clear professional manner.

For more information please call us on (515) 635-1760.

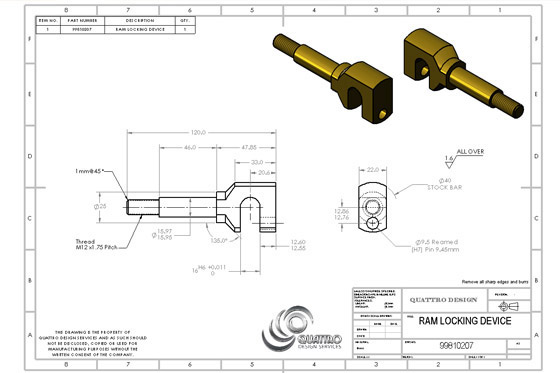

A Few Examples of Equipment Assemblies

Here at MS Design Innovations we take your hand drawn sketches and make them come to life, allowing for validation of the design before any material is cut saving on mistakes, time wasting and costs. – this dear should be in the “about us” section, a great selling point as to why they should hire you.

- Mechanical Engineering Design

- AutoCAD

- SolidWorks

- Industrial Design

- R&D

- Project Management

- Design Documentation

- Detailed Manufacturing Drawings

- Bills of Materials

- Proof of Concept

- Prototyping

- Design Documentation

- Complex Problem Solving

- Operational Excellence

- Continuous Improvement

- Organizational Skills

- Customer Focus

- Manufacturing Processes

- Design Concepts

- Reverse Engineering

- MS Office

- Communication Skills

- Quality Minded

Innovative Sr. R&D and Automation Engineer with a diverse skillset and 25+ years’ experience

Passionate about delivering business impactful engineered solutions as a member of a multidisciplinary team

Track record in conception, design, development, integration within Automation and stand alone machines.

Launched own consultancy, Quattro Design Services Ltd 2016 and MS Designs in 2023 for American based clients to better service them.

Established business as a provider of bespoke designs covering conveyors, machinery, automation lines,pick & place, and material handling equipment

Three current projects with three clients, two under NDAs. the third is a seaweed processing line, just installed

At forefront of full process through requirements gathering, research, BOM creation, and laser profiling

Partnering with clients in automation, pharmaceutical, food, material handling, automotive, agricultural and other sectors

Creating assembly drawings, including bill of materials and detail drawings

Visiting clients and imparting technical expertise/solutions

Controlling and maintaining design documents, including manuals, product documentation, and standards

Experience using 3D and 2D CAD software (SolidWorks, AutoCAD) for mechanical and automation engineering

Track record in a hands-on setting developing, assembling, and testing mechanical solutions

Innovation Champion and operational excellence

Accustomed to leading projects and partnerships while maintaining strong relationships with clients

Self-motivated with proven initiative, organization skills, problem-solving capabilities, and strong work ethic

Committed to continuous professional development and welcomes chances to support cutting-edge projects

Excellent written/verbal communication and presentation skills.

About the Director

Mark Sanders

For over 30 years I’ve been allied to the mechanical engineering industry, mostly within the automation industry. I’m a versatile engineer with a wide range of hands-on knowledge in the design and development of mechanical process equipment, including Vibratory machinery (bowl feeders, Linear feeders, Bulk storage hoppers etc).

With extensive knowledge of special purpose machinery from prototype design through to manufacture, I have been heavily involved in the assembly, test and fault finding.

Since 2005, I have been predominantly been based within company design departments responsible for, and producing, detailed technical specifications in both 2D drawings and 3D models. To support my work, I’ve invested in SolidWorks latest software including AutoCAD. The software provides the ability to calculate and report on product loadings and stresses should that be required.

Working closely with clients to fully understand and identify their requirements, explore all options to narrow down the solution, refine and create in 3D image for discussion, run simulation (if required) and explore costs sustainability before breaking down and detailing components ready for manufacturing then issue drawings, BOM, Cutting lists etc.

From philosophies to be evolved or projects needing to progress, I provide total support from start to completion.

See examples for services I offer and is a snapshot of my work.

I am investigating those companies that may require my services either immediately or in the future. Being a small company, I can offer a very personal service against any requirements from small component parts to large machines.

I can be contacted by mobile (515) 635-1760 or or email at info@msdesigninnovations.com.

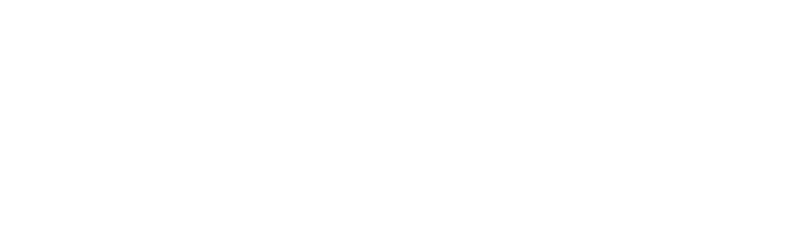

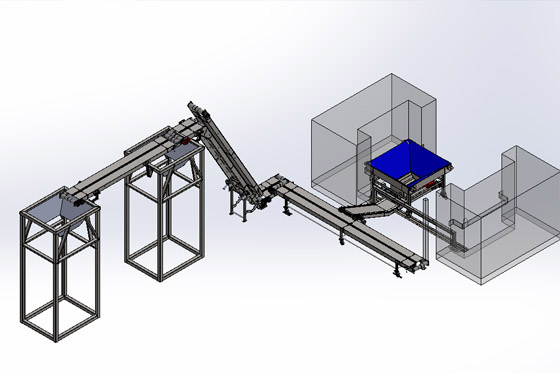

2D CAD Drawings

We produce high quality fully compliant drawings which include:

• Concept Drawings

• Fabrication Drawings

• Manufacturing Drawings.

3D CAD Service

We offer CAD services for important projects and take pride in the delivery of the final designs we create for our clients.

CAD Conversion

We take your ideas, whether its just a hand sketch or other formats and turn them into a drawing and 3D model, bringing them to life.

Rendering

Is taking the 3D model to the next step, by generating it with realistic graphics, by applying material, texture and also adding lighting and background scenes.

Reverse Engineering

The process of Reverse Engineering is to take an existing product apart to see how it works for the purpose of duplication or enhancing the object.